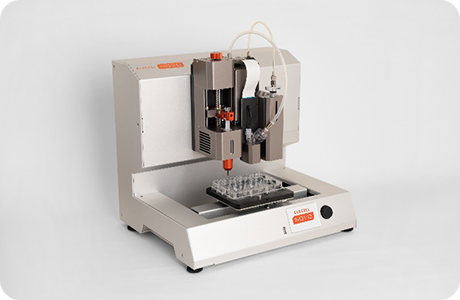

3D Bioprinter NOVO

Academic 3D bioprinter for tissue engineering researchers using various biomaterials

Product Specification

| Number of Nozzles | 2 |

|---|---|

| 3D Modeling / Editing Type | 3D / 2.5D |

| Build volume | 130 mm x 86 mm x 30 mm |

| Supported file formats | .gcode, .stl, .obj, .amf |

| Desktop application compatibility | Windows 10/11 |

| Power supply | Input: 100-240VAC, 50/60Hz, Output: V12DC, 37.5A, 450W |

| Build surface compatibility | Petri dishes and multi-well plates (6 to 384 wells) |

| Software | U-Studio + G-code Editor |

| Operating temperature range | 15 - 30 °C |

| Outer dimensions (D x W x H) | 350 mm x 320 mm x 350 mm |

| Weight | 17.8 kg |

| Printable Material | --- |

NOVO Special Features

-

Portability and biological stability

⦁ Installed in BSC Cabinet and Clean Bench

⦁ Easy to move and change work location

⦁ Maintain stable experimental environment

-

Various Crosslinking Method

⦁ Low viscosity biomaterials can be sprayed in a droplet manner, and crosslinking is possible by pH, enzyme, and chemical (ion) in addition to UV LED, Temperature reaction.

⦁ Easy 3D stacking of low viscosity materials through step-by-step curing through layer-by-layer crosslinking

-

User Friendly Functions

⦁ Cell Homogenization : Automatic cell circulation function to prevent cell sedimentation and clumping

⦁ Auto Calibration: Nozzle position and output Build-plate leveling function

⦁ Built-in editor provided so even beginners can easily implement 3D shapes

⦁ Clecell’ U-Studio Software

⦁ Available for use with general 3D modeling files (STL, etc.) and G-Code Editor for experts

NOVO Printhead

- Syringe pump Extruder

- Droplet dispenser

- Nebulizer

-

⦁ For syringe pump extruder, precise extrusion of biomaterials in 0.1 µL units is possible.

⦁ Ensuring accurate printing of tissues and cells and consistency of results

-

⦁ Applicable to various temperature conditions (Extruder : 10°C - 65°C / Droplet dispenser : 15°C - 50°C)

⦁ Improved cell viability and structural stability through temperature control

-

⦁ Droplet technology using pneumatic pressure

⦁ Complex structures can be formed through precise injection of low-viscosity materials.

⦁ Crosslink solution micro-coating (spraying) is possible through the nebulizer channel.

⦁ Quick drying possible using air dryer

-

⦁ [Syringe pump Extruder] 3mL, 5mL Syringe Available

⦁ [Droplet dispenser] 5mL Syringe Available

⦁ Ensures flexibility and efficiency of experiments

NOVO Special Feature

|

NOVO |

A |

|

| Print Technology |

Syringe-based extrusion Pneumatic Droplet with Microvalve Base |

syringe-based extrusion Available |

| Printhead volume |

Syringe pump Extruder : 3 mL~ 5mL Droplet dispenser : 5mL 3mL, 5mL Syringe available |

Extruder : 2.5 mL |

| Printhead dispensed volume CV |

Syringe pump Extruder : < 10% @ 10 µL for water Droplet Dispenser : < 10% @ 10 nL for water *Droplet Minimum injection volume 10nL / 1000x higher resolution than others |

Extruder : < 10% @ 10 µL for water |

| Printhead temperature range |

Extruder Up to 65-degree, Droplet Dispenser Up to 50-degree |

Extruder Heating Unavailabl |

| Nebulizer Crosslinking |

Nebulizer(pH, chemical, enzyme) The only way to make low-viscosity materials by layering |

x |

| Software |

2.5 Modeling 3D Modeling Possible G-Code Edit |

3D Modeling Available |